Quote

Logistics Consulting and Warehousing Management Solutions

Their Challenge

Automotive supply chains are founded on a system of harmony between man and machine: automated assembly with human organization build the means to connect us to our communities. But the path to harmonization is as complex as it is vast--and synchronizing a new facility to the production timeline is no easy task.

An OEM's Tier 1 Supplier approached KWE with a proposition: to consult and collaborate on the implementation of a turn-key operation with a six-month timeline.

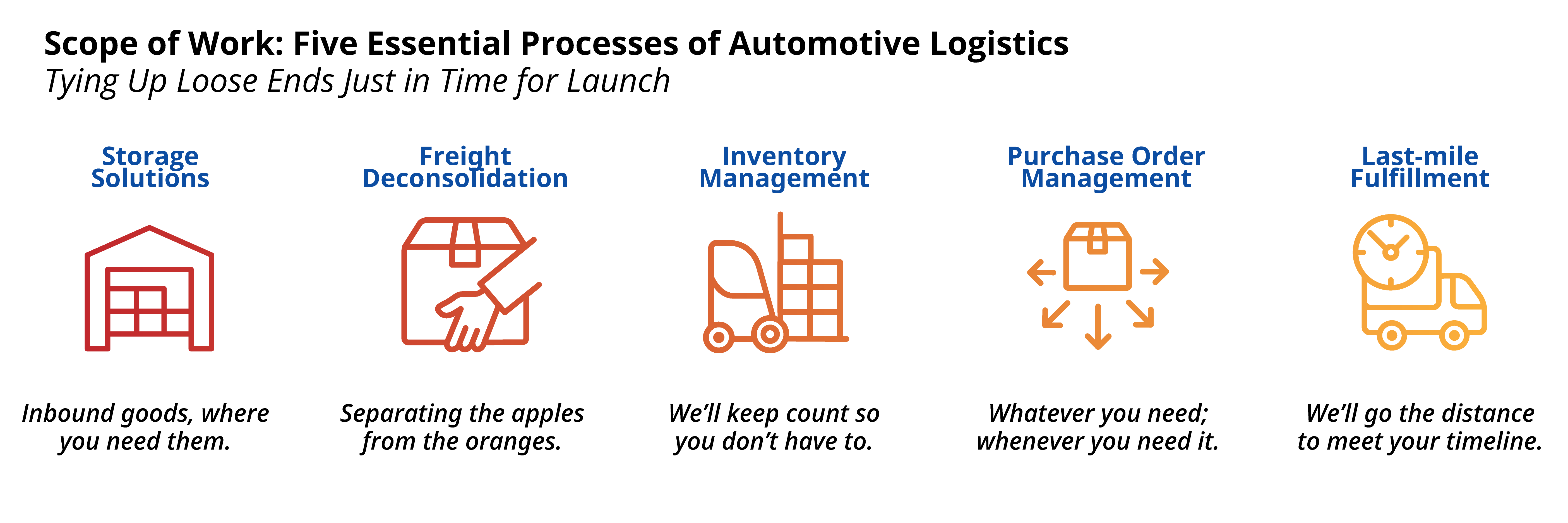

With their operations based in China, the client sought to purchase a facility optimally located to key transit hubs, with site specifications ideal for both heavy inbound cargo flow and daily distribution. Once selected, our project specialists would develop management systems, standard operating procedures, and digital architecture to integrate with a globally synchronized supply chain.

Our Solution

Drawing on our vast logistics management experience, KWE's project team worked closely with the client to procure an appropriate facility, reviewing building design and layout for warehouse functionality.

Designated areas and operations processes were established for cargo receipt, storage, pick & pack, kit assembly, outbound distribution, and quality assurance.

The Results

The client accomplished the highly successful, on-time launch of a 368,000 ft² facility with sufficient space to accommodate a twice-daily shift operation, with more than 60 fulltime employees processing over 1400 units per hour--a significant increase thanks to efficient layout design and operations training.

Case Study

Another story might interest you:

Contact Us

How can we help you go faster?